-

DC Axial Fans

Each model undergoes rigorous testing to ensure minimal noise even under high airflow and pressure conditions. Delta's highly automated, precision-driven assembly process guarantees consistent quality across all units.

Series-

AFB

Delta AFB Series DC axial fans deliver high airflow and reliable cooling for servers, networking equipment, industrial control systems, power supplies, and other environments requiring efficient thermal management.

View Details -

AFC

View Details -

ASB

View Details -

AUB

View Details -

AUC

View Details -

EFB

View Details -

EFC

View Details -

FA

View Details -

FC

FC - CONTROL BOARD

View Details -

FFB

View Details -

FFC

View Details -

GFB

View Details -

GFC

View Details -

GFM

View Details -

KSB

View Details -

PFB

View Details -

PFC

View Details -

PFM

View Details -

PFR

View Details -

QFR

View Details -

TAA

TAA Series fans are general axial fans with a sleeve bearing system for multiple industry cooling applications. TAA Series fans are made for highly cost-sensitive products.

View Details -

TFA

View Details -

TFC

View Details -

TFD

TFD Series fans are general axial fans with a sleeve bearing system for multiple industry cooling applications. TFD Series fans are made for highly cost-sensitive products.

View Details -

THA

View Details -

THB

THB

View Details -

THD

View Details

-

-

DC Centrifugal Blowers

POWERFUL – DURABLE – QUIETLY EFFICIENT. Delta DC blowers are built to last, run quietly, and perform at the highest industry levels—even in the harshest environments.

Series-

BCB

View Details -

BFB

View Details -

BFM

View Details -

BFN

View Details -

BSB

View Details -

BUB

View Details -

KDB

View Details -

KFB

View Details -

KSB

View Details -

ND

View Details -

SFB

View Details -

TCA

Designed for high efficiency and lower power consumption.

View Details

The fan engineers use a diagonal hub and optimize blade design to provide lower noise and better system cooling solution.

This standard DC open blower has Delta’s highly ball bearing system that is ideal for telecom and other industry applications

-

-

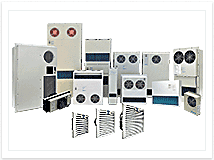

Climate Thermal Solutions

Delta’s cabinet thermal solutions—including thermoelectric coolers, heat exchangers, filter fans, and air conditioners—are engineered to maintain optimal temperatures in enclosed spaces, protecting sensitive electronics from heat buildup and ensuring reliable, contaminant-free operation across data centers and production lines. Contact our sales team to discuss the advantages of each cabinet thermal solution.

Series-

AIR CONDITIONERS

Delta industrial air conditioners use active compressor-based cooling to keep internal enclosure temperatures below ambient. These slim air cons employ a variable speed DC inverter compressor and dual rotor design to achieve a high COP with reduced vibration and low operating noise. All Delta air conditioners feature Delta’s high quality DC brushless fans engineered to run continuously for a minimum of 80,000 hours, or nine years.

View Details -

AIR TO AIR HEAT EXCHANGERS

Delta air-to-air heat exchangers are a closed-loop system with advanced fan and core technology to bring internal enclosure temperatures to ambient. Delta heat exchangers feature Delta DC brushless fans engineered to run continuously for 80,000 hours, or nine years. Standard and custom designs are available.

View Details -

THERMOELECTRIC COOLERS

Delta thermoelectric coolers provide slightly below ambient cooling in tight spaces. A TEC module is a sandwich of components (Peltier chips, heat sinks and fans) which provides cooling without the need for refrigerant or a compressor. All Delta TEC’s incorporate Delta DC brushless fans engineered to run continuously for 80,000 hours, or nine years. Standard and custom designs are available.

View Details -

HEATERS

Cabinet heaters provide protection for enclosed electronics and equipment in low-temperature environments. Delta heaters have a Positive Temperature Coefficient (PTC) heating element for increased safety and reduced operating costs. PTC heaters generate only the heat necessary for the desired temperature, versus at a constant rate, saving energy while helping to prevent overheating and burnout. Standard and custom designs are available.

View Details -

Filter Fans (HEF)

High CFM filter fans for dust sensitive industrial applications with easy maintenance.

Suggested Applications: Industrial Automation, Automotive Assembly, Package Handling Equipment, Food and Beverage Process Controls, and Wind Energy Systems.

View Details

-

-

EC Fans & Blowers

With 40 manufacturing facilities, 61 R&D labs and 7,000 R&D engineers worldwide, Delta Electronics is a global leader in fans & thermal management, power electronics and other innovative energy-efficient solutions.

Delta offers a range of electronically commutated (EC) centrifugal blowers and axial fans for high-powered air movement applications.

Series-

EC Centrifugal Blowers

Delta offers EC centrifugal blower assemblies from 190mm to 660mm diameter. All blowers include inlet cone / nozzle. The wheel is plastic or metal depending on the part number. Mounting brackets are available on some models. Contact Us for pricing and availability of Delta EC centrifugal blowers.

Delta EC fan, a greener and smarter design for a better tomorrow.

View Details -

EC Axial Fans

Our EC axial fans 630mm and larger feature a square 4-hole metal mounting plate for ease of installation, and a robust metal electronics access cover (versus plastic) to help prevent cracking and water intrusion. Contact Us for pricing and availability of Delta EC axial fans.

View Details

-

-

Commercial Fridge Fans & Motors

Delta-designed refrigerator fans with dedicated bearing systems operate in low-temperature environments of up to -40°F. Our novel blade design is a low noise solution, creating abundant airflow within the system tunnel while maintaining a uniform internal refrigerator temperature.

Series-

DC Refrigeration Fans

Delta designed our refrigerator fans for low-temperature environments with a dedicated bearing system allowing our fans to work at an operational temperature of -40°F without freezing. Our unique blade design allows unrestricted airflow with lower system tunnel noise while keeping a steady temperature inside your refrigerator. Delta's advanced motor driver circuit technology achieves high efficiency and low vibration at the same time while also offering a PWM function for a wider speed range adjustment.

View Details -

EC Commercial Refrigeration Fans

Our brushless DC motor technology is Electronically Commutated (EC) — featuring integrated AC to DC inverters and magnetic rotors — offers significant power savings over AC motor fans while maintaining AC source-input compatibility. Customers can expect up to 70% power savings by using Delta EC motor-based fans, so now you can offer high-performance, power-saving HVAC and Commercial Refrigerator products to your clients.

View Details -

Commercial Refrigeration Motors

The Electronically Commutated (EC) motors based on brushless DC motors use built-in AC to DC converter and magnet rotors to attain more power savings than regular AC motors. Our EC motors are designed for maximum reliability and power efficiency for HVAC applications.

View Details

-

-

Thermal Management

Delta's super slim blower technology is an important factor in making the Ultrabook computer possible. Delta's latest energy-efficient electronically commutated fan series are perfectly designed for industrial applications, commercial building HVAC, and precision cooling for data centers.

Series-

Thermal Management Solution

With over 3 decades of design & manufacturing expertise, Delta has launched a complete air cooling solution portfolio with cost effectiveness and high reliability to the world, ranging from different heatsink applications to advanced heat pipe/vapor chamber variation. Supported by its strong engineering team as well as worldwide production bases, Delta utilizes handy simulation tools and its self-developed database of intelligence to tailor the right cooling solution just perfect to the needs of customer with professional efficiency.

View Details -

Liquid Cooling Solution

As the computing capability of the data center increases, IT equipment generates more heat, which must be addressed to handle higher heat density and prevent system failures. Delta's liquid cooling solution is capable of efficiently managing the significant heat generated by IT equipment, surpassing the performance of traditional air-cooling solutions.

View Details

Delta has matching water-cooled cold plate and cooling liquid distribution unit (CDU) products available for Level 6 board-level solutions, Level 10 complete system assembly solutions, and even Level 11 system integration solutions. -

Portable Thermal Solution

A portable thermal solution is designed to manage the heat produced by chips and other electronic components. This design combines essential elements like fans, heat transfer components (heat pipes, VC, etc.), heat exchangers, and structural metal or plastic parts to create compact and efficient products. These products are lightweight and have portable dimensions, making them suitable for everyday use and versatile applications.

View Details

-

-

Fan Trays / Controller Boards

Offer customers optimal performance design and total thermal solution from fan unit design to fan tray design and manufacturing

Products

Fans and Thermal Management

Delta's super slim blower technology is an important factor in making the Ultrabook computer possible. Delta's latest energy-efficient electronically commutated fan series are perfectly designed for industrial applications, commercial building HVAC, and precision cooling for data centers.

Delta’s Thermal Management Offerings

Temperature is a crucial variable in mechanical and industrial processes. Appropriate thermal management is critical to maximizing performance and preventing system disruptions. You can eliminate potential failure points in your systems with targeted precision cooling.

But what is thermal management, and how can it protect your business?

In addition to maintaining your system’s temperature within its operating range through our air and liquid cooling technology, Delta’s cutting-edge thermal electronics solutions allow your business to unlock amazing efficiency gains, reduce energy costs, and maximize performance.

Here is a selection of our product categories and how they benefit your thermal management system.

Category List

- 00~+60⁰C 1 item

- -00~+70⁰C 2 items

- -10~+40⁰C 1 item

- -10~+50⁰C 6 items

- -10~+60⁰C 320 items

- -10~+70⁰C 761 items

- -10~+75⁰C 1 item

- -10~+80⁰C 4 items

- -10~+85⁰C 3 items

- -10~+90⁰C 5 items

- -20~+60⁰C 2 items

- -20~+65⁰C 1 item

- -20~+70⁰C 8 items

- -20~+75⁰C 1 item

- -20~+90⁰C 4 items

- -20~+105⁰C 1 item

- -25~+60⁰C 3 items

- -25~+70⁰C 9 items

- -40~+40⁰C 3 items

- -40~+55⁰C 7 items

- -40~+60⁰C 8 items

- -40~+65⁰C 2 items

- -40~+70⁰C 7 items

- -40~+75⁰C 3 items

- -40~+80⁰C 2 items

- -40~+85⁰C 2 items

- -40~+105⁰C 1 item

- 10.0 dB(A) 4 items

- 13.0 dB(A) 3 items

- 16.0 dB(A) 9 items

- 18.0 dB(A) 7 items

- 18.5 dB(A) 1 item

- 20.0 dB(A) 7 items

- 20.5 dB(A) 1 item

- 21.0 dB(A) 9 items

- 21.5 dB(A) 6 items

- 22.0 dB(A) 10 items

- 22.5 dB(A) 3 items

- 23.0 dB(A) 7 items

- 23.5 dB(A) 7 items

- 24.0 dB(A) 28 items

- 24.5 dB(A) 8 items

- 25.0 dB(A) 14 items

- 26.0 dB(A) 15 items

- 26.5 dB(A) 12 items

- 27.0 dB(A) 15 items

- 27.5 dB(A) 2 items

- 28.0 dB(A) 34 items

- 28.1 dB(A) 1 item

- 28.5 dB(A) 13 items

- 29.0 dB(A) 18 items

- 29.5 dB(A) 2 items

- 30.0 dB(A) 16 items

- 30.5 dB(A) 12 items

- 31.0 dB(A) 31 items

- 31.5 dB(A) 14 items

- 32.0 dB(A) 17 items

- 32.7 dB(A) 1 item

- 32.5 dB(A) 24 items

- 33.0 dB(A) 15 items

- 33.5 dB(A) 8 items

- 33.8 dB(A) 1 item

- 34.0 dB(A) 25 items

- 34.5 dB(A) 7 items

- 35.0 dB(A) 9 items

- 35.5 dB(A) 13 items

- 35.9 dB(A) 1 item

- 36.0 dB(A) 13 items

- 36.2 dB(A) 1 item

- 36.4 dB(A) 2 items

- 36.5 dB(A) 8 items

- 36.7 dB(A) 1 item

- 37.0 dB(A) 11 items

- 37.3 dB(A) 2 items

- 37.5 dB(A) 6 items

- 38.0 dB(A) 20 items

- 38.5 dB(A) 13 items

- 39.0 dB(A) 12 items

- 39.5 dB(A) 6 items

- 40.0 dB(A) 15 items

- 40.0dB(A) @ 0.3M 1 item

- 40.5 dB(A) 11 items

- 41.0 dB(A) 17 items

- 41.2 dB(A) 3 items

- 41.5 dB(A) 14 items

- 41.7 dB(A) 1 item

- 42.0 dB(A) 3 items

- 42.0 dB(A) @ 0.5M 1 item

- 42.5 dB(A) 19 items

- 43.0 dB(A) 5 items

- 43.5 dB(A) 2 items

- 44.0 dB(A) 16 items

- 44.1 dB(A) 6 items

- 44.2 dB(A) 3 items

- 44.3 dB(A) 1 item

- 44.5 dB(A) 23 items

- 45.0 dB(A) 24 items

- 45.4 dB(A) 3 items

- 45.5 dB(A) 1 item

- 46.0 dB(A) 16 items

- 46.5 dB(A) 25 items

- 47.0 dB(A) 3 items

- 47.5 dB(A) 14 items

- 48.0 dB(A) 14 items

- 48.2 dB(A) 5 items

- 48.5 dB(A) 8 items

- 48.6 dB(A) 4 items

- 49.5 dB(A) 3 items

- 49.6 dB(A) 1 item

- 49.7 dB(A) 3 items

- 50.0 dB(A) 11 items

- 50.5 dB(A) 12 items

- 50.8 dB(A) 1 item

- 51.0 dB(A) 8 items

- 51.2 dB(A) 3 items

- 51.5 dB(A) 3 items

- 51.8 dB(A) 1 item

- 51.9 dB(A) 2 items

- 52.0 dB(A) 5 items

- 52.3 dB(A) 2 items

- 52.5 dB(A) 13 items

- 53.0 dB(A) 22 items

- 53.5 dB(A) 4 items

- 54.0 dB(A) 14 items

- 54.3 dB(A) 1 item

- 54.4 dB(A) 1 item

- 54.5 dB(A) 5 items

- 55.0 dB(A) 20 items

- 55.5 dB(A) 9 items

- 56.0 dB(A) 2 items

- 56.4 dB(A) 8 items

- 56.5 dB(A) 8 items

- 57.0 dB(A) 13 items

- 57.5 dB(A) 9 items

- 57.9 dB(A) 1 item

- 58.0 dB(A) 2 items

- 58.5 dB(A) 11 items

- 59.0 dB(A) 15 items

- 59.5 dB(A) 1 item

- 59.9 dB(A) 1 item

- 60.0 dB(A) 9 items

- 60.5 dB(A) 5 items

- 61.0 dB(A) 7 items

- 61.5 dB(A) 6 items

- 62.0 dB(A) 6 items

- 62.2 dB(A) 2 items

- 62.5 dB(A) 1 item

- 63.0 dB(A) 3 items

- 63.3 dB(A) 1 item

- 63.4 dB(A) 1 item

- 63.7 dB(A) 1 item

- 63.9 dB(A) 1 item

- 64.0 dB(A) 20 items

- 64.5 dB(A) 2 items

- 65.0 dB(A) 21 items

- 65.1 dB(A) 1 item

- 65.5 dB(A) 2 items

- 66.0 dB(A) 6 items

- 66.5 dB(A) 18 items

- 66.8 dB(A) 1 item

- 67.0 dB(A) 2 items

- 67.3 dB(A) 1 item

- 67.7 dB(A) 3 items

- 67.8 dB(A) 3 items

- 68.0 dB(A) 1 item

- 68.5 dB(A) 2 items

- 68.6 dB(A) 1 item

- 69.0 dB(A) 4 items

- 69.3 dB(A) 1 item

- 69.4 dB(A) 2 items

- 70.0 dB(A) 9 items

- 70.5 dB(A) 3 items

- 70.8 dB(A) 1 item

- 71.0 dB(A) 3 items

- 71.5 dB(A) 2 items

- 72.0 dB(A) 1 item

- 72.5 dB(A) 2 items

- 72.6 dB(A) 1 item

- 73.0 dB(A) 4 items

- 73.3 dB(A) 1 item

- 73.5 dB(A) 2 items

- 74.0 dB(A) 1 item

- 74.5 dB(A) 1 item

- 75.0 dB(A) 1 item

- 75.5 dB(A) 1 item

- 76.5 dB(A) 1 item

- 77.0 dB(A) 2 items

- 77.5 dB(A) 2 items

- 78.0 dB(A) 3 items

- 78.5 dB(A) 3 items

- 79.0 dB(A) 3 items

- 80.0 dB(A) 1 item

- 82.0 dB(A) 3 items

- 3600 Hrs@70⁰C 2 items

- 5000 Hrs@90⁰C 1 item

- 7000 Hrs@40⁰C 2 items

- 8000 Hrs@105⁰C 1 item

- 15000 Hrs@25⁰C 1 item

- 20000 Hrs@40⁰C 19 items

- 20000 Hrs@70⁰C 5 items

- 30000 Hrs@40°C 84 items

- 30000 Hrs@55⁰C 5 items

- 40000 Hrs@40⁰C 2 items

- 50000 Hrs@40⁰C 176 items

- 50000 Hrs@50⁰C 2 items

- 50000 Hrs@70⁰C 4 items

- 50000 Hrs@85⁰C 3 items

- 60000 Hrs@40⁰C 1 item

- 61320 Hrs@45⁰C 1 item

- 70000 Hrs@40⁰C 508 items

- 70000 Hrs@40°C 258 items

- 80000 Hrs@40⁰C 38 items

- 2.0 - 3.5 VDC 5 items

- 2.5 - 5.5 VDC 2 items

- 3.0 - 5.5 VDC 2 items

- 3.5 - 5.5 VDC 1 item

- 3.5 - 13.2 VDC 2 items

- 4.0 - 5.5 VDC 24 items

- 4.0 - 13.2 VDC 24 items

- 4.0 - 13.6 VDC 2 items

- 4.0 - 13.8 VDC 47 items

- 4.5 - 5.5 VDC 55 items

- 4.5 - 13.2 VDC 16 items

- 4.5 - 13.8 VDC 7 items

- 4.75 - 13.8 VDC 1 item

- 5.0 - 12.5 VDC 1 item

- 5.0 - 12.6 VDC 7 items

- 5.0 - 12.8 VDC 1 item

- 5.0 - 13.2 VDC 20 items

- 5.0 - 13.5 VDC 2 items

- 5.0 - 13.8 VDC 49 items

- 5.1 - 13.8 VDC 1 item

- 5.5 - 13.2 VDC 6 items

- 5.5 - 13.8 VDC 1 item

- 6.0 - 13.0 VDC 1 item

- 6.0 - 13.2 VDC 8 items

- 6.0 - 13.8 VDC 5 items

- 6.0 - 14.0 VDC 5 items

- 7.0 - 12.6 VDC 8 items

- 7.0 - 13.0 VDC 2 items

- 7.0 - 13.2 VDC 76 items

- 7.0 - 13.6 VDC 1 item

- 7.0 - 13.8 VDC 205 items

- 7.0 - 15.0 VDC 6 items

- 7.0 - 27.6 VDC 20 items

- 8.0 - 13.2 VDC 13 items

- 8.0 - 14.0 VDC 1 item

- 9.0 - 12.6 VDC 1 item

- 9.0 - 13.8 VDC 1 item

- 9.0 - 16.0 VDC 1 item

- 10.0 - 13.2 VDC 2 items

- 10.0 - 13.8 VDC 7 items

- 10.2 - 13.2 VDC 1 item

- 10.2 - 13.8 VDC 1 item

- 10.8 - 12.6 VDC 21 items

- 10.8 - 12.8 VDC 1 item

- 10.8 - 13.2 VDC 76 items

- 10.8 - 13.8 VDC 4 items

- 12.0 - 30.0 VDC 3 items

- 12.0 - 16.80 VDC 1 item

- 12.0 - 27.60 VDC 1 item

- 12.0 - 28.0 VDC 14 items

- 14.0 - 26.4 VDC 69 items

- 14.0 - 26.5 VDC 6 items

- 14.0 - 27.6 VDC 87 items

- 14.0 - 27.6VDC 65 items

- 14.0 - 28.0 VDC 2 items

- 16.0 - 26.4 VDC 10 items

- 18.0 - 27.5 VDC 1 item

- 18.0 - 26.0 VDC 1 item

- 18.0 - 26.4 VDC 1 item

- 18.0 - 28.0 VDC 1 item

- 20.0 - 56.0 VDC 4 items

- 20.4 - 26.4VDC 2 items

- 20.4 - 27.6VDC 1 item

- 21.6 - 26.4 VDC 14 items

- 21.6 - 26.4VDC 2 items

- 21.6-26.4VDC 14 items

- 22.0 - 26.0 VDC 1 item

- 24.0 - 56.0 VDC 1 item

- 24.0 - 60.0 VDC 1 item

- 24.0 - 72.0 VDC 2 items

- 28.0 - 53.0 VDC 3 items

- 28.0 - 56.0VDC 5 items

- 28.0 - 53.0VDC 2 items

- 28.0 - 56.0 VDC 11 items

- 30.0 - 56.0 VDC 1 item

- 30.0 - 60.0 VDC 1 item

- 33.0 - 52.8 VDC 2 items

- 34.0 - 56.0 VDC 2 items

- 36.0 - 59.0 VDC 1 item

- 36.0 - 60.0 VDC 3 items

- 36.0 - 60.0VDC 19 items

- 36.0 - 72.0 VDC 2 items

- 36.0 - 75.0 VDC 27 items

- 36.0 - 75.0VDC 7 items

- 36.0 - 56.0 VDC 2 items

- 42.0 - 60.0 VDC 1 item

- 100.0 - 240.0 VDC 1 item

- 100 - 240 VAC 5 items

- 110 - 240 VAC 5 items

- 115 - 230 VAC 2 items

- 200 - 240 VAC 3 items

- 0.02 A 1 item

- 0.03 A 13 items

- 0.04 A 14 items

- 0.05 A 36 items

- 0.06 A 57 items

- 0.07 A 36 items

- 0.08 A 45 items

- 0.09 A 38 items

- 0.10 A 48 items

- 0.11 A 31 items

- 0.12 A 40 items

- 0.13 A 31 items

- 0.14 A 37 items

- 0.15 A 21 items

- 0.16 A 42 items

- 0.17 A 13 items

- 0.18 A 32 items

- 0.19 A 8 items

- 0.20 A 14 items

- 0.21 A 7 items

- 0.22 A 9 items

- 0.23 A 23 items

- 0.24 A 23 items

- 0.25 A 17 items

- 0.26 A 11 items

- 0.27 A 17 items

- 0.28 A 13 items

- 0.29 A 2 items

- 0.30 A 6 items

- 0.31 A 5 items

- 0.32 A 10 items

- 0.33 A 15 items

- 0.34 A 13 items

- 0.35 A 11 items

- 0.36 A 3 items

- 0.37 A 3 items

- 0.38 A 13 items

- 0.39 A 4 items

- 0.40 A 20 items

- 0.42 A 6 items

- 0.43 A 8 items

- 0.44 A 3 items

- 0.45 A 7 items

- 0.46 A 3 items

- 0.47 A 3 items

- 0.48 A 4 items

- 0.50 A 29 items

- 0.52 A 3 items

- 0.53 A 4 items

- 0.54 A 3 items

- 0.55 A 8 items

- 0.56 A 7 items

- 0.58 A 3 items

- 0.60 A 10 items

- 0.62 A 3 items

- 0.63 A 10 items

- 0.65 A 13 items

- 0.66 A 1 item

- 0.68 A 4 items

- 0.69 A 4 items

- 0.70 A 3 items

- 0.71 A 1 item

- 0.74 A 3 items

- 0.75 A 7 items

- 0.77 A 4 items

- 0.79 A 2 items

- 0.80 A 4 items

- 0.83 A 1 item

- 0.84 A 5 items

- 0.85 A 4 items

- 0.88 A 1 item

- 0.89 A 1 item

- 0.90 A 10 items

- 0.91 A 3 items

- 0.93 A 1 item

- 0.94 A 1 item

- 0.95 A 2 items

- 0.97 A 6 items

- 0.99 A 1 item

- 1.00 A 21 items

- 1.02 A 1 item

- 1.05 A 4 items

- 1.10 A 7 items

- 1.12 A 1 item

- 1.15 A 5 items

- 1.17 A 7 items

- 1.20 A 3 items

- 1.23 A 1 item

- 1.25 A 2 items

- 1.26 A 3 items

- 1.30 A 3 items

- 1.3 A 3 items

- 1.35 A 10 items

- 1.40 A 4 items

- 1.45 A 11 items

- 1.50 A 10 items

- 1.55 A 5 items

- 1.57 A 2 items

- 1.60 A 7 items

- 1.79 A 1 item

- 1.80 A 2 items

- 1.96 A 2 items

- 2.00 A 6 items

- 2.07 A 2 items

- 2.10 A 2 items

- 2.15 A 1 item

- 2.17 A 1 item

- 2.20 A 1 item

- 2.27 A 1 item

- 2.30 A 3 items

- 2.37 A 1 item

- 2.40 A 1 item

- 2.45 A 2 items

- 2.70 A 2 items

- 2.75 A 5 items

- 2.80 A 1 item

- 2.90 A 2 items

- 3.00 A 2 items

- 3.10 A 2 items

- 3.14 A 1 item

- 3.20 A 2 items

- 3.25 A 2 items

- 3.30 A 3 items

- 3.35 A 1 item

- 3.40 A 2 items

- 3.50 A 4 items

- 3.60 A 1 item

- 3.65 A 4 items

- 3.70 A 2 items

- 3.75 A 2 items

- 3.90 A 1 item

- 3.95 A 1 item

- 4.00 A 5 items

- 4.15 A 1 item

- 4.20 A 1 item

- 4.30 A 2 items

- 4.50 A 2 items

- 4.60 A 1 item

- 4.90 A 1 item

- 5.00 A 3 items

- 5.20 A 1 item

- 5.80 A 1 item

- 8.00 A 1 item

- 8.27 A 1 item

- 15.0 A 1 item

- AFB 451 items

- AFC 7 items

- AFL 15 items

- ASB 31 items

- AUB 35 items

- AUC 1 item

- BCB 9 items

- BFB 151 items

- BFM 1 item

- BSB 6 items

- BUB 4 items

- EFB 99 items

- EFC 2 items

- EUB 2 items

- FA 1 item

- FC 1 item

- FFB 146 items

- FFC 2 items

- GFB 5 items

- GFC 12 items

- GFM 2 items

- KDB 2 items

- KSB 2 items

- KFB 3 items

- MR 3 items

- ND 1 item

- PFB 90 items

- PFC 7 items

- PFM 4 items

- PFR 13 items

- QFR 38 items

- SFB 1 item

- TAA 1 item

- TCA 1 item

- TFA 3 items

- TFC 1 item

- TFD 1 item

- THA 4 items

- THD 12 items

- THB 13 items

- HEC 19 items

- HEF 6 items

- HEH 14 items

- HET 10 items

- HEX 13 items

- GTB 25 items

- GTM 7 items

- GTW 17 items